EWI Plasma-cutting capabilities allow for the high-speed production of complex items that require precise shapes and cuts. Our lights-out automation helps drastically reduce lead times, getting you the parts faster.

Plasma Cutting is ideal for highly complex parts that require precise dimensions and cuts. The ability to cut intricate shapes also eliminates the need for additional operations. Plasma cutting also causes no damage or warping, even to thin materials and offers precise holes and edges. We also have an experienced Engineering team that uses nesting to increase sheet utilization, which results in less waste and lower costs.

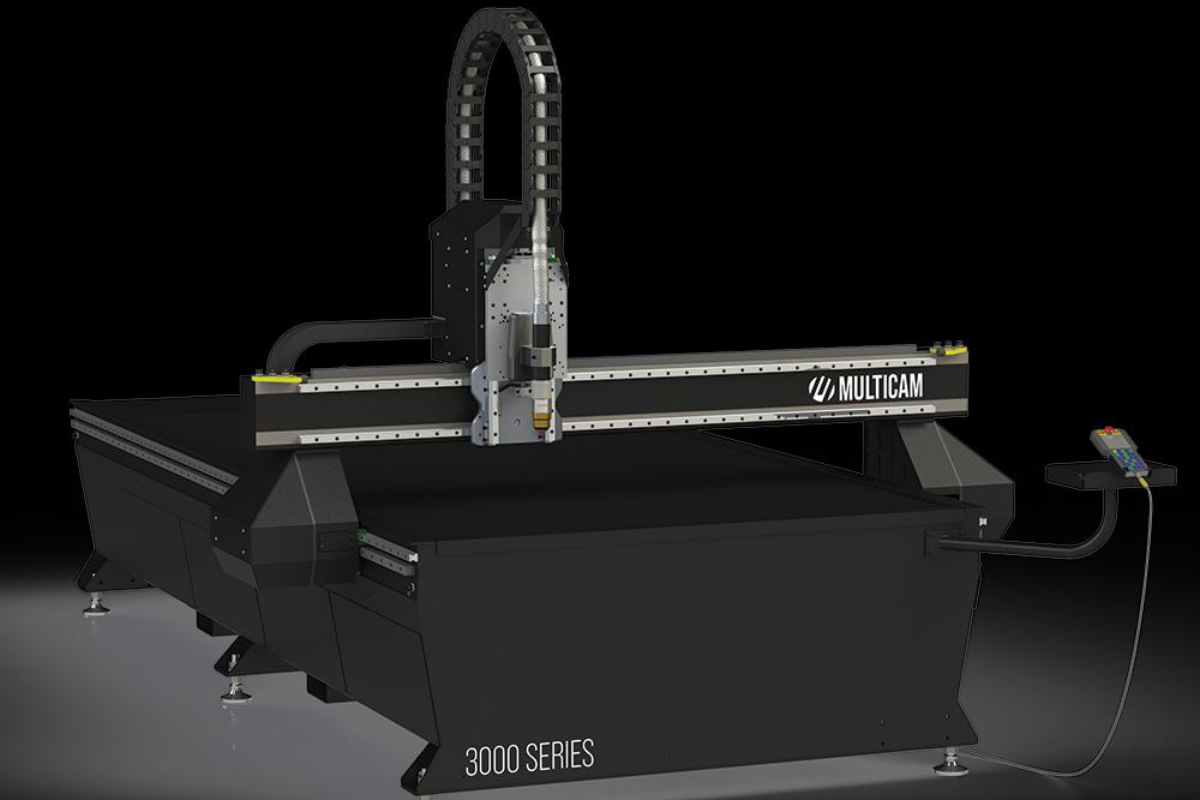

Working area: 60” X 120”

Repeatability: +/- 0.001”

Rapid Traverse: 2300 IPM

Material Cut: Steel, Stainless Steel, Aluminum, Brass, Bronze, Copper, Diamond Plate, Expanded metal, Galvanized metal